Green Remediation Focus

Rainbow Valley Citrus Maintenance Yard Facility

Goodyear, AZ

RCRA Corrective Action, Leaking Underground Storage Tanks

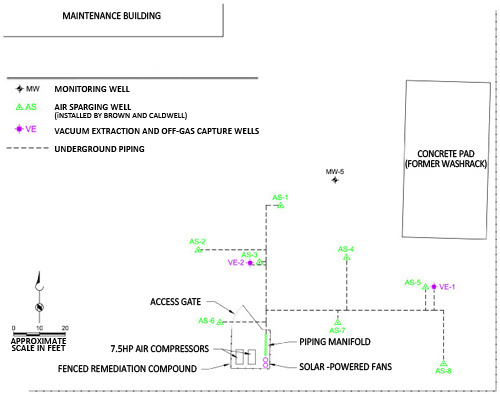

Cleanup Objectives: Remediate groundwater containing petroleum hydrocarbons released from two underground storage tanks to levels no longer posing risk. Following removal of both tanks, remedial activities in and around the contaminant source area of this two-acre site, located approximately 40 miles southwest of Phoenix, Arizona, involved installation of eight onsite monitoring wells; in situ air stripping through eight newly installed air sparging wells; vacuum extraction of phase-separated gasoline from two of the monitoring wells; and vapor extraction (VE) and off-gas collection from these two monitoring wells with highest hydrocarbon concentrations.

Green Remediation Strategy: Use renewable energy rather than grid-supplied electricity to power equipment needed to collect off-gas from the two VE wells during air sparging. The strategy involved installing a 2.5 watt solar-powered fan assembly directly on a vent pipe for each well; due to louver design of the fan housing, this equipment additionally drew passive wind energy that supplemented the off-gas collection system.

Results:

- Removed 500 gallons of free-phase gasoline (mixed with groundwater) from the two targeted monitoring wells via a vacuum extraction truck deployed over a single eight-hour day

- Disposed of the recovered gasoline mixture at a commercial waste oil facility nearby (within 30 miles)

- Operated the eight-well air sparging system successfully (at an air injection rate averaging 25 cubic feet per minute [cfm]) from August 2012 through May 2013, without shutdown attributable to the off-gas collection system

- Achieved effective rates of air flow for off-gas collection in both VE wells during the 10-month operating period, with average air flows of 1 cfm and 4 cfm

- Collected off-gas effectively during the 10 months of active air sparging, with average photoionization detector (PID) readings of approximately 50 ppmv in both VE wells

- Avoided consumption of an estimated 20,000 kWh of electricity during the 10 months of air sparging through use of off-gas equipment powered by renewable energy, including passive wind flow potentially reaching 62 CFM in a wind speed of 11 miles per hour; this estimate assumed alternate use of a 5 hp standard electrical blower with a run time of 75%, which was estimated to demand 2,000 kWh each month over 10 months

- Avoided emission of approximately 13.8 metric tons of carbon dioxide (equivalent) through use of renewable energy, when compared to using grid-supplied electricity to power a blower for off-gas collection

- Achieved a comparable rate of off-gas capture and overall air sparging duration to reach remediation goals in the source area, when compared to alternative use of a standard electrical blower for ventilation

- Injected a chemical oxidant (catalyzed sodium persulfate) approximately five months after air sparging ceased, for in situ spot treatment of downgradient groundwater

- Completed site cleanup in April 2014, approximately 11 months after air sparging shutdown

- Saved an estimated $12,750 in cleanup costs associated with 10-month deployment of the off-gas collection system, which involved capital costs of $500 ($250 for each solar-powered fan assembly) and minimal installation and maintenance costs; in contrast, costs for using a standard 5 hp electrical blower were predicted at $10,000 in rental fees (at $1,000 per month) plus $3,000 for electricity (at an estimated $300 per month)

Property End Use: Agricultural residence, equipment storage and repair facility

Point of Contact: Samar Bhuyan, Arizona Department of Environmental Quality

Update: October 2014