Green Remediation Focus

British Petroleum Site

Casper, Wyoming

WY Voluntary Cleanup

Cleanup Objectives: Remediate gasoline-contaminated ground water for 50 to 100 years

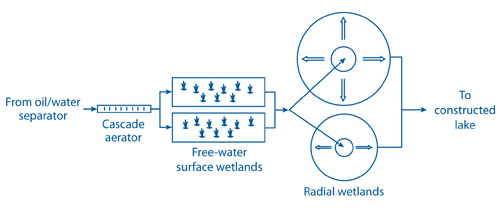

Green Remediation Strategy: Installed radial-flow engineered wetlands operating in tandem with free-water surface wetlands and a cascading aeration system

- Employed Smart Growth principles to complement conversion of the site's former refinery to an office park and recreational facilities

- Designed wetland components for subsurface locations as much as possible to increase operational control and reduce offensive odors or insects

- Constructed radial-flow treatment beds consisting of crushed concrete previously reclaimed during refinery demolition

- Insulated wetland treatment beds with a six-inch layer of mulch to accommodate temperatures reaching -35°F

- Planted emergent wetland plants such as bulrushes, switchgrass, and cordgrass in each of the four wetland areas

Results:

- Treats up to 700,000 gallons of contaminated ground water each day

- Achieves a 50% reduction in BTEX concentrations when compared to influent of the pre-wetlands aeration process

- Achieves non-detectable concentrations of benzene and other hydrocarbons in water prior to discharge into a basin created by former refinery effluent discharge

- Operates year-round despite cold climate

- Incurred construction cost of $3.4 million, in contrast to projected $15.9 million for alternative pump-and-treat system employing air stripping and catalytic oxidation

- Found beneficial use for onsite demolition material

- Uses passive-energy systems to biodegrade contaminants

- Allowed for office park occupation within 10 months after the aerated/engineered wetland system began operating

Point of Contact: Vickie Meredith, WY Department of Environmental Quality