Green Remediation Focus

Pemaco Superfund Site

Mayfield, California

Superfund NPL

Cleanup Objectives: Remove volatile organic compounds (VOCs) such as trichloroethene from soil and ground water at this 1.4-acre site along the Los Angeles River. The 1.4-acre Pemaco site was formerly used for chemical blending operations and is now incorporated into a four-acre community park. Past and current remediation activities have involved: (1) soil capping and limited excavation; (2) high-vacuum dual-phase extraction; (3) a soil vapor extraction (SVE) system; and (4) electrical resistance heating of soil supported by flameless thermal oxidation for vapors.

Green Remediation Strategy: The strategy has focused on renewable energy generation and energy conservation, material reuse and conservation, and water preservation. Best management practices (BMPs) implemented to date include:

- Using onsite photovoltaics (PV) to generate electricity that offsets utility-supplied energy consumed by the soil or groundwater treatment systems.

- Modifying, downsizing or terminating remediation system components to achieve greater energy and operational efficiencies as site cleanup progresses and site conditions change over time.

- Utilizing local personnel for operation and maintenance (O&M) of the treatment system and for periodic sampling, to minimize offsite commute-related fuel consumption and air emissions.

- Identifying future uses of equipment no longer needed for remediation.

- Developing a green infrastructure supporting current and future use of the site and adjoining property.

- Integrating remedial O&M activities into planning redevelopment of the site and adjoining property.

Results:

Renewable Energy Generation & Energy Conservation

- Generating an average of 5,700 kilowatt hours (kWh) of electricity each year through operation of a 3.4 kW PV system installed above the onsite treatment plant. Between 2007 start-up and 2016, the PV system generated a cumulative total of 51,000 kWh of electricity used directly at the treatment plant. The amount of generated electricity is equivalent to approximately 2% of the electricity currently purchased from the utility each year for remediation purposes.

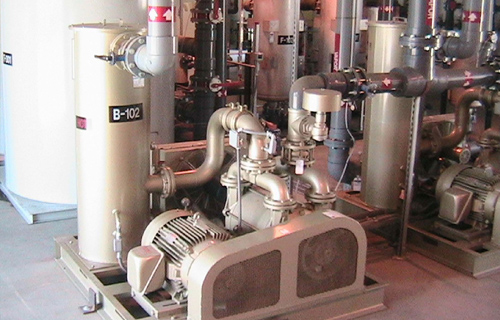

- Conserving a total of approximately 86,000 kWh of electricity per month since 2013 through optimization of the treatment system. Optimization involved installing a variable frequency drive (VFD) on each of two air blowers used for SVE, switching from continuous to intermittent operation of the dual-phase extraction wells, and ceasing groundwater extraction from wells where VOC concentrations were reduced to below the site-specific remediation criteria. Costs for electricity purchasing accordingly decreased, by approximately $6,700 each month.

Air Quality Preservation

- Reducing offsite carbon dioxide emissions by approximately four metric tons each year through generation of 5,700 kWh of electricity from a renewable resource. This emission reduction is equivalent to 9,601 fewer car miles driven annually.

- Reducing carbon dioxide emissions by approximately 60 metric tons each month due to optimization of the treatment system and the associated reduction in fossil fuel-derived electricity consumption.

- Reducing offsite fuel consumption and emissions associated with travel by the treatment plant operator. Since 2012, daily O&M activities and monthly sampling have been conducted by a plant operator commuting 15 miles, in contrast to previously contracted staff commuting 80 miles.

Water Preservation

- Reducing stormwater runoff from the site by approximately 281,000 gallons each year due to installation of vegetation across the 1.4-acre former Pemaco site. The associated increase in subsurface infiltration of rainwater continues to benefit the Maywood Riverfront Park, which includes additional properties purchased by the City of Maywood in 2006.

- Fostering aquifer recharge and reducing pollutants discharged into the Los Angeles River through use of green infrastructure techniques such as creating vegetated berms and bioswales within the park.

Material Reuse & Conservation

- Enabled offsite reuse of the flameless thermal oxidizer (FTO) formerly supporting electrical resistance heating. The FTO and ancillary equipment were sold through a federal General Service Administration auction to a commercial buyer, Bering Sea Environmental LLC. Associated onsite work involved: (1) disconnecting existing piping, utility and controls; (2) removing the scrubber tower and roof penetration loop; (3) physically removing the equipment; and (4) re-piping the vapor treatment system and controls.

- Reduced the number of groundwater samples collected annually by more than 50%, from approximately 430 samples each year. This reduction was achieved by: (1) discontinuing sampling in wells where contaminant concentrations remained below the site-specific remediation criteria over four consecutive quarters; and (2) changing sampling frequency in 88 wells from quarterly to semi-annual. Associated material, labor, analytical and other direct costs consequently decreased by approximately $230,000 each year.

- Reduced the number of process water and vapor samples collected annually by 25% and 83%, respectively, which resulted in less consumption of sampling-related material and other resources and decreased annual sampling costs by $54,000.

- Reduced the overall site-wide O&M costs by an estimated total of $437,000 per year due to the monitoring activity reductions, well eliminations, modified treatment rates and associated staffing reductions.

Property End Use: Expansion of the adjoining riverfront park

Point of Contact: Greg Harvey, U.S. Environmental Protection Agency, Region 9

Update: February 2017