Green Remediation Focus

Former Telles Ranch Site

Poston, Arizona

RCRA Corrective Action, Leaking Underground Storage Tanks

Cleanup Objectives: Remediate soil and groundwater contaminated by petroleum products or other liquid materials that historically leaked from storage tanks at or near an 8-acre site currently used for farm equipment maintenance. The site is located seven miles south of Poston, Arizona, on the Colorado River Indian Tribes Reservation and adjacent to property formerly housing a World War II relocation camp using multiple aboveground and underground storage tanks. Initial cleanup activities involved removing four onsite 8,000-gallon aboveground storage tanks (ASTS) and interconnecting piping and soil contaminated by gasoline- and diesel-range organics, benzene and methyl tertiary-butyl ether (MTBE). Current efforts focus on operating a free-product recovery system targeting a 1.5-acre area where product thicknesses reached 3.5 feet within monitoring wells and product visibly seeped into an onsite irrigation drainage canal. In 2018, it was determined that the contamination likely stems from the WWII-era activities and the U.S. Department of Interior was named the responsible party.

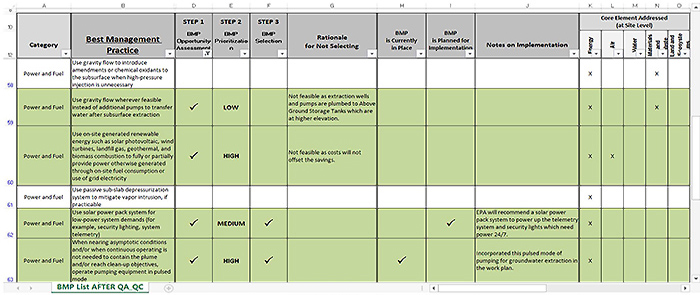

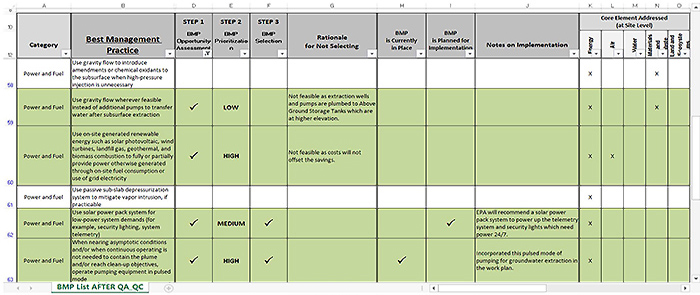

Green Remediation Strategy: The ASTM Standard Guide for Greener Cleanups (E2893-16) was used to evaluate best management practices (BMPs) for ongoing cleanup activities. The process of screening all BMPs listed in the Standard's "BMP checklist" (Appendix X3) resulted in identification of 34 BMPs applying to the site. Of these, 17 were determined to have the greatest ability to reduce the cleanup project's environmental footprint and therefore assigned a high priority; nine were assigned a medium priority and eight were assigned a low priority. Further evaluation resulted in selecting 18 BMPs for continued use, including eight high- or medium-priority BMPs bringing a high level of implementation ease, effectiveness and reliability:

- Reuse existing onsite structures for treatment systems, material storage, sample management and other operations.

- Revise the sampling plan over time to eliminate "non-detect" wells from the sampling routine or reduce sampling frequency at non-detect wells.

- Schedule sampling activities to coincide with operation and maintenance (O&M) visits.

- Use a passive/no purge system for groundwater sampling.

- Use devices or equipment that increase automation expected to optimize remediation systems and minimize site visits.

- Reuse or recycle routine waste materials, construction materials, and recovered products of economic value.

- Use local or nearby hotels for worker lodging.

- Use carpooling for worker commutes or periodic site visits.

Additionally, four high- or medium-priority BMPs were selected for future implementation:

- Purchase renewable energy through a local utility's green energy program or via renewable energy certificates for use in powering cleanup activities.

- Use solar power packs to operate devices or equipment with low energy demands.

- Recycle or reuse un-used, spent or uncontaminated equipment or infrastructure.

- Use electric, hybrid, ethanol or compressed natural gas vehicles instead of conventionally-fueled vehicles.

Results:

- Optimized siting of new structures required for ongoing cleanup activities, by choosing a location adjacent to an existing farm building and in close proximity to the product recovery wells; one 3,000-gallon AST was needed to store recovered product, and a small building was needed to store sampling and O&M equipment. Use of the strategic location for these structures reduced the amount of needed security fencing (by approximately 20 feet), provided easy access to an existing power source and avoided additional land disturbance.

- Reduced the number of monitoring wells to be sampled from 20 to 11, at a semi-annual rather than quarterly frequency, based on an evaluation of groundwater sampling data collected over more than 10 years. Additionally, the project schedule now requires concurrent groundwater sampling events and O&M visits, which include measuring depths to product and water in the recovery wells and testing of the individual pneumatic skimmer pumps. The updated sampling plan reduces the number of truck trips to and from the site, the amount of consumed materials (such as single-use containers and laboratory chemicals), and the volume of waste generated in the field and at offsite laboratories.

- Using a telemetry system to monitor product levels in the AST storing recovered product, which enables the frequency of O&M visits to occur quarterly rather than monthly; the frequency will be reduced further as product recovery volume becomes stable or declines.

- Using passive, no-purge techniques for all groundwater sampling events, which reduces the amount of wastewater requiring offsite management, conserves groundwater and reduces field mobilization materials and activities.

- Recovered a total of 105,000 gallons of free product for subsequent transfer to an offsite recycling facility, as of May 2016; approximately 10 to 20% of product remaining in the subsurface (estimated at 100,000 to 200,000 gallons as of July 2017) is expected to be recovered and recycled in the future. The product recovery system that began operating in 2008 consists of skimmer pumps in eight monitoring/recovery wells, two skimmer pumps in a 140-foot-long free product interceptor pipe, and product-transfer piping connecting the skimmer pumps to the 3,000-gallon AST. Free product that is periodically purged from wells without skimmer pumps also is stored temporarily in the AST.

- Using a hotel located 16 miles from the site (in Parker, Arizona) to lodge personnel visiting the site at an estimated frequency of 12 trips per year; each year, this approach avoids the fuel consumption and vehicle emissions associated with driving approximately 960 additional miles if using accommodations in the next closest and larger town (Lake Havasu City, Arizona). Additionally, carpools are used for ground transport of visitors whenever possible.

Property End Use: Continued use as a farm equipment maintenance facility.

Point of Contact: Rebecca Jamison, U.S. Environmental Protection Agency, Region 9

Visit the online ASTM Public Library of E2893 Greener Cleanup Reports to access the Telles Ranch greener cleanup report, which details the BMP evaluation in a technical summary in accordance with the Standard's documentation and self-certification process.

Update: January 2019